- Introduction

- Key Takeaways

- 1. Material Selection

- 2. Fabrication Processes and Their Costs

- 3. Tolerances

- 4. Surface Finishing

- 5. Hardware Considerations

- 6. Strategies for Cost Optimization

- Conclusion

Introduction

Sheet metal fabrication is critical across various industries, providing structural components for items as varied as household appliances and industrial equipment. However, understanding the complex factors influencing fabrication costs can be challenging. This guide explores the primary cost drivers and offers practical strategies to manage and optimize expenses.

Key Takeaways

- Selecting the right material affects both the performance of the part and its cost.

- Fabrication processes impact the cost, by factors such as part geometry and tooling.

- Surface finishes, hardware, and tolerances can be optimized to reduce costs.

- Efficient part nesting and design simplification are effective cost-saving measures.

1. Material Selection

In sheet metal fabrication, each material presents its own set of unique characteristics, influencing not just performance but also economic considerations. Let's break down the properties and typical applications of aluminum, stainless steel, and mild steel:

Types of Materials

Aluminum

Aluminum is known for its lightweight nature, which makes it particularly suited for industries where reducing weight is paramount. However, its higher cost compared to steel makes it less attractive for projects where pure cost per kilogram is a key concern.

- Weight Savings

- Aluminum is extensively used in aerospace and automotive applications, as it can significantly improve fuel efficiency by cutting down on mass.

- Parts which need to be air freighted, or expressed, will be much lighter and therefore less costly.

- Corrosion Resistance

- The oxide layer that forms naturally on its surface also provides excellent corrosion resistance, shielding it from environmental damage. This means parts can last longer in the field and reduce cost of ownership.

- As aluminum already has good corrosion resistance, no secondary surface finishing is necessarily needed, cutting down on total part cost.

- Improved Heat Efficiency

- Aluminum offers good thermal and electrical conductivity, making it ideal for components where heat or electricity transfer is necessary, like heat exchangers or electrical enclosures.

- This can cut down on the need for active cooling or heat exchanges, reducing total BOM cost.

Stainless Steel

- Corrosion Resistance

- With its chromium content, stainless steel resists rust and corrosion, making it ideal for environments with high moisture or chemical exposure.

- Its ability to maintain structural integrity in harsh conditions adds to its appeal in sterile and clean settings.

- Strength and Durability

- The material's high strength supports long-lasting applications, resisting wear and deformation over time.

- Its durability offsets the moderate initial cost by reducing replacement and maintenance expenses.

- Applications

- Common uses include kitchen appliances, medical instruments, and the food and beverage industry.

- Its hygienic properties make it a top choice for environments that demand cleanliness and longevity.

Mild Steel

Mild steel is known for its affordability and versatility, making it a popular choice for cost-conscious projects. While it lacks the inherent corrosion resistance of stainless steel, it compensates with ease of fabrication and low material cost.

- Cost Efficiency

- As the most economical option, mild steel is widely used in large-scale projects where budget constraints are critical.

- Its low cost allows for extensive use in construction and general fabrication.

- Fabrication Versatility

- The material can be easily welded, bent, and shaped, making it adaptable to a variety of designs.

- Surface treatments such as galvanization or painting are often applied to enhance rust resistance.

- Applications

- Mild steel is commonly used in automotive frames, building components, and general fabrications.

- It is suitable for environments where extreme durability or corrosion resistance is not required.

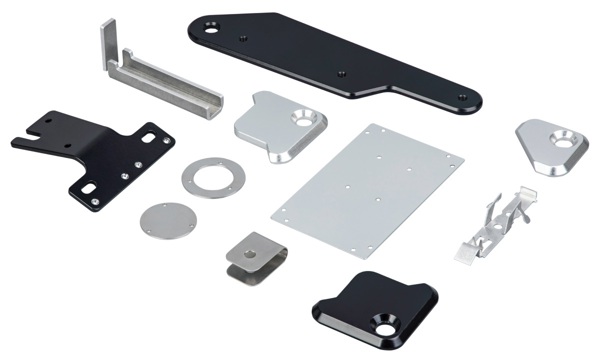

Fig. 1: Sheet Metal Parts from Komacut

Material Grades

Different grades within each material type affect cost and performance. Here is a list of common grades of these metals:

Aluminum Grades

- 5052 Aluminum

- Known for its high corrosion resistance, especially in marine environments, and weldability. It is used in marine, automotive, and other corrosive environments.

- 6061 Aluminum

- One of the most versatile aluminum alloys, often used for structural applications. It is recognized for its strength and good machinability.

- 7075 Aluminum

- A high-strength aluminum alloy often used in aerospace applications, especially where the strength-to-weight ratio is critical.

- 2024 Aluminum

- Noted for excellent fatigue resistance, commonly found in aerospace structures.

Stainless Steel Grades

- 304 Stainless Steel

- This is one of the most common and versatile stainless steel alloys, known for its good corrosion resistance and ease of fabrication. It is commonly used in food-grade applications.

- 316 Stainless Steel

- Contains molybdenum, which increases its resistance to corrosion, particularly in chloride environments like marine or chemical settings.

- 430 Stainless Steel

- This is a ferritic stainless steel with good corrosion resistance at a lower cost, often used in domestic appliances and automotive trim.

- 410 Stainless Steel

- A martensitic grade that is heat-treatable, offering good hardness and wear resistance. This is commonly used in cutlery and valves.

Mild Steel Grades

- A36 Steel

- The most common structural steel grade, known for its good weldability and ductility. It is widely used in construction.

- 1018 Steel

- A commonly used low-carbon steel, appreciated for its machinability, surface finish, and ease of welding.

- 1045 Steel

- A medium-carbon steel with higher strength and hardness compared to lower-carbon steel, often used for shafts and axles.

- 1020 Steel

- This low-carbon steel offers excellent ductility and weldability, often used in light structural work.

These grades are industry standards and are widely accepted in various engineering applications. Each alloy and grade has specific properties that meet the required performance in different environments and industries.

Material Availability and Sourcing

- Local Sourcing: Reduces shipping costs, tariffs, and lead times; supports quicker production schedules.

- International Sourcing: May offer lower material prices but can incur additional costs from tariffs, increased shipping fees, and longer lead times, potentially offsetting savings.

Material Thickness

Thickness impacts cost, weight, and structural integrity:

- Thicker Materials: These are more expensive due to higher material volume, provide greater strength, and are used in structural applications.

- Thinner Materials: Less costly and reduces overall weight; may require reinforcement; used in applications like automotive body panels to enhance fuel efficiency.

Selecting the right material is essential in sheet metal fabrication, as it directly affects both cost and performance. Key factors influencing material selection include the type of material, its grade, availability, and sourcing options, and the material's thickness.

| Metal Materials | Type | Approximate Cost (RMB) | Approximate Cost (USD) |

|---|---|---|---|

| SPCC | Cold Rolled Steel | ¥5.25 | $0.75 |

| SGCC | Galvanized Steel | ¥6.52 | $0.90 |

| SAPH440 | Hot Rolled Steel | ¥5.10 | $0.75 |

| Q235 | Carbon Steel | ¥4.80 | $0.70 |

| Q345 | Low Alloy Steel | ¥5.40 | $0.80 |

| Spring Steel-65Mn | Spring Steel | ¥9.00 | $1.25 |

| AL5052 H32 | Aluminum Alloy | ¥20.00 | $2.80 |

| AL6061 T6 | Aluminum Alloy | ¥23.00 | $3.20 |

| SS301 | Stainless Steel | ¥18.00 | $2.50 |

| SS304 | Stainless Steel | ¥21.00 | $3.00 |

| SS316 | Stainless Steel | ¥24.00 | $2.40 |

Table 1: Approximate Cost per Kilogram of Common Metal Materials

2. Fabrication Processes and Their Costs

Laser Cutting

- Factors Influencing Laser Cutting Costs: Costs depend on material type, thickness, and cut complexity. Harder materials and thicker sheets require more energy and time, increasing expenses. Intricate designs take longer to cut, adding to the cost.

- Design Optimization for Laser Cutting: Simplifying designs by reducing unnecessary complexity lowers cutting time and costs. Streamlined patterns and fewer intricate details make the process more efficient.

CNC Bending

- Impact of Part Geometry: The number of bends, angles, and complexity directly influence costs. More bends and complex geometries require additional setup and machine time, increasing expenses.

- Tooling and Setup Time: Tooling and setup are significant cost factors. Standardizing designs to use common tooling reduces setup time. Optimizing operations by grouping similar bends can lead to cost savings.

Stamping and Punching

- Cost-Effectiveness in High-Volume Production: For large batches, stamping, and punching are more cost-effective than laser cutting due to lower per-unit costs after initial tooling investment.

- One-Off Setups vs. Large-Batch Production: High initial setup costs make stamping less economical for small runs. In contrast, large-batch production spreads these costs over many units, reducing the overall expense per part.

Hardware Insertion

- Impact of Hardware Choice: Choosing standard hardware like PEM nuts over specialized fasteners reduces costs. The type and quality of hardware affect both material expenses and insertion time.

- Automation in High-Volume Runs: Automating hardware insertion increases efficiency and lowers labor costs in very high production volumes, leading to significant savings.

Welding

- Different techniques like MIG, TIG, and spot welding vary in cost and speed.

- Techniques requiring more skill and time, such as TIG welding, are typically more expensive.

- Automated welding will require some investment in jigs, but the ROI will be excellent if you can reduce manual welder time – skilled welders are expensive and rare.

- Welding is preferred when a strong, permanent joint is needed, especially for thick materials or designs where rivets or bolts are unsuitable.

Riveting

- Riveting is cost-effective, requires less skilled labor, and is quicker than welding. It provides strong joints without the heat distortion that welding can cause. Riveting vs. Welding: Riveting is better for joining dissimilar or thin metals and allows for some flexibility in the joint. Welding offers a stronger, permanent bond but at a higher cost and with potential material distortion.

Fig. 2: Komacut's Instant Sheet Metal Quotation Platform

Fig. 2: Komacut's Instant Sheet Metal Quotation Platform

3. Tolerances

Optimizing tolerances is crucial in sheet metal fabrication, as they directly impact production costs and the functionality of the final product.

Standard vs. Tight Tolerances

Tighter tolerances require more precise manufacturing processes, leading to increased production time and higher costs. Achieving tight tolerances may involve advanced machinery, additional quality control measures, and increased material waste due to stricter acceptance criteria. For example, maintaining a tolerance of ±0.01 mm might necessitate slower machining speeds and specialized equipment compared to a standard tolerance of ±0.1 mm.

When Tight Tolerances Are Necessary

Tight tolerances are essential when parts must fit together precisely or function in a way that leaves little room for deviation. Applications in aerospace, medical devices, and precision engineering often demand high tolerances to ensure safety, reliability, and optimal performance. For instance, components in a hydraulic system require tight tolerances to prevent leaks and maintain pressure.

Cost Savings by Relaxing Tolerances

Relaxing tolerances where high precision is unnecessary can lead to significant cost savings without compromising functionality. For example, if a decorative panel does not interact with other components, specifying standard tolerances can reduce machining time and costs. You might change a tolerance from ±0.05 mm to ±0.5 mm on non-critical dimensions, simplifying production processes and reducing scrap rates, ultimately lowering overall expenses.

4. Surface Finishing

Surface finishing enhances both the appearance and performance of sheet metal parts. Selecting the appropriate finish involves balancing cost, functionality, and aesthetic appeal.

Types of Surface Finishes

- Powder Coating: Involves applying a dry powder electrostatically and curing it under heat to form a protective layer. It offers a durable finish with a wide range of colors, suitable for both indoor and outdoor applications.

- Anodizing: Commonly used on aluminum, anodizing increases corrosion resistance and allows for coloring the metal through dyes. It creates a hard, wear-resistant surface ideal for electronic components and architectural elements.

- Galvanizing: Coats steel with a layer of zinc to prevent corrosion. Hot-dip galvanizing is effective for outdoor structures and components exposed to harsh environments due to its robust protection against rust.

- Polishing: Enhances the metal's surface by making it smoother and more reflective. Often used for stainless steel, polishing is primarily for aesthetic purposes in products like appliances and decorative fixtures.

Fig. 3: Powder Coated Metal Part

Cost Considerations

The cost of surface finishing depends on the type of finish, part size, and complexity.

- Powder coating and galvanizing are generally cost-effective for larger parts and batches as they can be automated more easily.

- Anodizing and zinc plating are generally fairly low-cost processes, as parts can be easily batch processed, however, the yield of parts can be reduced due to the damage during the process, which will count towards the total cost.

- Any kind of polishing or brushing that is not automated is very labor-intensive, especially for complex geometries, and generally requires fairly skilled labor, increasing the overall cost.

- Customized colors and finishes will always cost more than off-the-shelf options; standard color finishes will provide cost savings, whether for anodization or powder coating.

Functional vs. Aesthetic Requirements

Surface finishing may be necessary for functional reasons, such as improving corrosion resistance, enhancing durability, or providing electrical insulation. For instance, galvanizing is crucial for steel structures exposed to the elements.

Alternatively, finishes might be applied purely for aesthetic appeal, like polished stainless steel for a mirror-like appearance. Determining the primary purpose of the finish helps in selecting the most cost-effective process without compromising on the necessary performance or desired look.

| Surface Finish | Characteristic | Advantages | Disadvantages | Cost |

|---|---|---|---|---|

| As-Machined Finish | Retains natural cut surface with minor tool marks | Economical, retains dimensional accuracy | May have visible tool marks, lacks smoothness | $ |

| Sand Blasting | Matte texture created by abrasive blasting | Aesthetic appeal, uniform surface finish | Can round off edges, not suitable for precision surfaces | $ |

| Anodizing | Oxide layer for protection and decorative finish | Enhances corrosion resistance, available in various colors | Limited to aluminum and titanium, may scratch or wear over time | $$ |

| Powder Coating | Durable, colorful protective layer | Impact and scratch-resistant, available in multiple colors | May add thickness, less suitable for tight tolerance parts | $$$ |

| Electropolishing | Smooth, bright, corrosion-resistant finish | High polish, ideal for sterile and clean applications | Involves chemical handling, limited to conductive materials | $$ |

| Brushed Finish | Satin-like sheen with uniform lines | Visually appealing, hides minor imperfections | The surface can retain scratches and may require maintenance | $ |

| Passivation | Enhanced corrosion resistance for stainless steel | Increases longevity in corrosive environments, no change to appearance | Requires acid baths, specific to stainless steel | $$ |

| Electroplating | A thin metal layer for protection or conductivity | Improves corrosion resistance, wear resistance, and conductivity | Limited thickness, may flake over time if improperly applied | $$ |

| Manual Polishing | High polish added – anything from standard to mirror finish | Part appearance can be great; minor surface defects can be buffed out or hidden | High cost; some difficulty for certain part shapes | $$$ |

Table 2: Comparative Analysis of Surface Finishes

Hardware Considerations

Selecting the right hardware is crucial for the functionality and cost-effectiveness of sheet metal fabrication projects.

Brand Selection: Premium Brands vs. OEMs:

- Premium brands like Penn Engineering offer high-quality hardware with consistent performance and reliability, essential for applications requiring strict adherence to specifications. However, they come at a higher cost.

- OEM alternatives or generic brands can be more cost-effective while still meeting necessary standards, and suitable for less critical applications.

- The choice depends on balancing performance requirements with budget constraints.

Custom vs. Standard Hardware

- Custom Hardware: Necessary when specific design requirements cannot be met by standard components, such as unique sizes or specialized features. Custom hardware increases costs due to design, tooling, the need for custom blank tools or large MOQs, and set-up costs for specialty production runs.

- Standard Off-the-Shelf Components: These are generally more affordable and readily available, reducing lead times and procurement costs. Whenever possible, designing to accommodate standard hardware can significantly lower overall expenses.

Material Differences in Hardware

- Stainless Steel Hardware: Offers superior corrosion resistance and strength but at a higher cost. Ideal for harsh environments or applications demanding high durability.

- Zinc-plated hardware: Provides decent corrosion resistance at a lower price point. Suitable for indoor or less demanding environments.

- Other Materials: Options like aluminum or plastic hardware may reduce weight and cost but might not offer the same strength or durability. The selection should align with the application's performance needs.

By carefully considering hardware brands, customization needs, and material choices, costs can be optimized without compromising the quality and functionality of the final product.

| Head Type | Drive Style | Size | Length (mm) | Zinc Plated Steel (USD) | Aluminum (USD) | Stainless (USD) | Brass (USD) |

|---|---|---|---|---|---|---|---|

| Hex Head | External Hex | M4 | 10 | 0.0203 | 0.4230 | 0.0176 | 0.0550 |

| M4 | 20 | 0.0319 | 0.6430 | 0.0265 | 0.0850 | ||

| M6 | 30 | 0.0667 | 0.1441 | 0.0966 | 0.2700 | ||

| M8 | 30 | 0.0377 | 0.2941 | 0.2500 | 0.4676 | ||

| Pan Head | Phillips | M4 | 10 | 0.0100 | 0.0450 | 0.0301 | 0.0425 |

| M4 | 20 | 0.0148 | 0.0650 | 0.0436 | 0.0700 | ||

| M6 | 30 | 0.0475 | 0.2050 | 0.1409 | 0.2450 | ||

| M8 | 30 | 0.1300 | 0.2294 | 0.1518 | 0.3294 | ||

| Flat Head | Phillips | M4 | 10 | 0.0159 | 0.0450 | 0.0168 | 0.0374 |

| M4 | 20 | 0.0254 | 0.0450 | 0.0268 | 0.0645 | ||

| M6 | 30 | 0.0641 | 0.3000 | 0.0803 | 0.2184 | ||

| M8 | 30 | 0.0441 | 0.2294 | 0.1618 | 0.2176 | ||

| M8 | 35 | 0.0471 | 0.2588 | 0.1765 | 0.2676 | ||

| Button Head | Phillips | M4 | 10 | 0.0135 | 0.0450 | 0.0184 | 0.0425 |

| M4 | 20 | 0.0169 | 0.0650 | 0.0267 | 0.0700 | ||

| M6 | 30 | 0.0541 | 0.2050 | 0.0874 | 0.2450 | ||

| M8 | 30 | 0.1500 | 0.7800 | 0.3000 | 0.7400 |

Table 3: Screw Pricing by Material and Size

6. Strategies for Cost Optimization

Implementing effective cost optimization strategies in sheet metal fabrication can lead to significant savings without compromising quality or functionality. These strategies focus on both process and material optimizations to enhance efficiency and reduce expenses.

Process Optimization

This can include a few aspects:

- Selecting the optimal process mix for the quantity and part type

- Processes like stamping can offer highly improved part costing by reducing waste and time in the process through tooling.

- Though tooling has upfront costs, processing costs can be reduced by 50% or more compared to more semi-automated processes like CNC bending if volumes are higher (several thousand pieces per lot is generally the break-even point depending on part design).

- Combining processes like laser cutting and turret punching can also provide significant cost savings. Be flexible and discuss with your manufacturer.

- Simplifying the processing by simplifying part requirements

- Reduce the number of intricate specifications or overly tight tolerances unless they are critical to the function of the part.

- Avoiding unnecessary customization can make the production process more straightforward and cost-effective.

- Discuss with your manufacturer which requirements are absolutely essential and which can be relaxed without compromising quality.

- Simplifying the process by modifying part or product design

- Simplifying designs to reduce unnecessary complexities can shorten setup times and machining processes.

- Adjusting features like the number of bends or eliminating superfluous details can lead to faster production cycles and lower labor costs.

- Standardizing components where possible can further reduce tooling changes and improve overall efficiency.

Material Optimization

- Material selection

- Selecting the appropriate material is crucial for balancing performance and cost.

- Over-specifying materials with unnecessary features or higher grades than needed can inflate expenses.

- By carefully evaluating the requirements of the application, companies can choose materials that meet specifications without incurring extra costs associated with excessive properties.

- Selecting the appropriate material is crucial for balancing performance and cost.

- Part consolidation

- Another effective strategy for material optimization.

- Combining multiple parts into a single sheet metal component can reduce assembly time and associated labor costs.

- This approach simplifies the manufacturing process by decreasing the number of individual parts, which can also enhance product reliability by reducing potential points of failure in assemblies.

- Another effective strategy for material optimization.

- Part Nesting

- The nesting of sheet metal parts is another critical issue – think of fitting your parts like Tetris blocks on a given sheet of metal material.

- The better the parts fit together without spaces in between means the less material wasted, and lower overall costs, this is because it allows manufacturers to arrange parts closely on the material sheet, maximizing usage and reducing scrap.

- There are online and open-source options for this (Deepnest, Powernest, etc.) that allow you to test optimal part designs.

- The nesting of sheet metal parts is another critical issue – think of fitting your parts like Tetris blocks on a given sheet of metal material.

Conclusion

Evaluating the various factors that influence the cost of sheet metal fabrication is crucial for optimizing both design and production. Careful material selection in choosing the right type, grade, and thickness can significantly affect costs and performance.

Process efficiency plays a vital role; optimizing fabrication methods like laser cutting, CNC bending, and surface finishing can lower expenses. Implementing cost-saving measures such as minimizing material waste, streamlining design elements, and consolidating parts can lead to substantial savings without compromising quality or functionality.

To effectively manage and reduce your sheet metal fabrication costs, it's essential to apply these strategies from the early stages of your project. Check out our Komacut website. At Komacut, we make this process easier by offering instant cost calculations for your sheet metal parts. Simply upload your 3D drawings, and our platform will provide you with a detailed cost estimate. This allows you to make informed decisions and optimize your designs for both performance and cost-efficiency.